WELCOME TO MATECH INDUSTRY LTD.

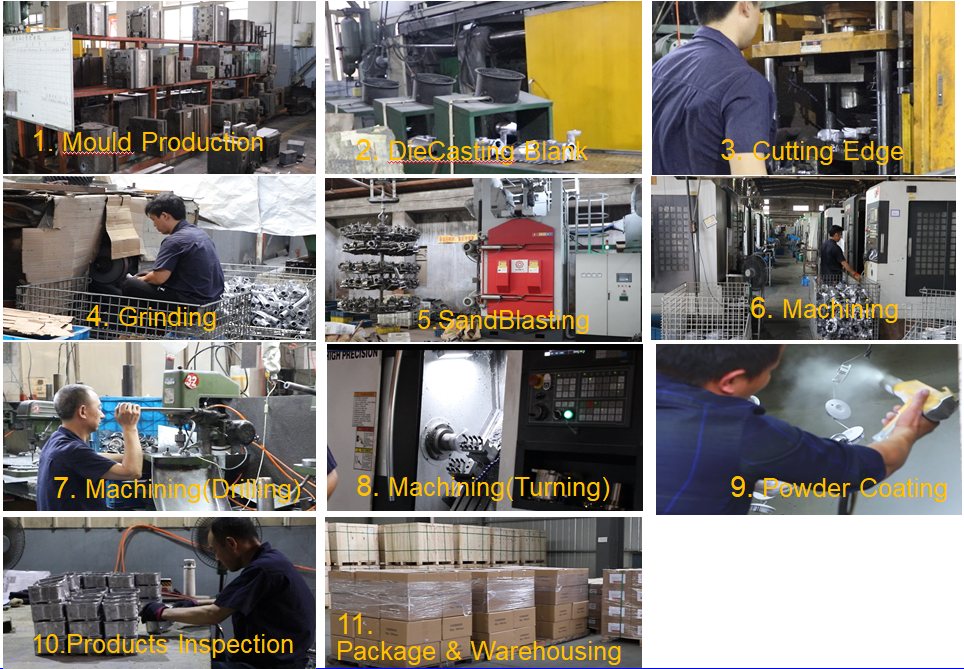

Matech Industry Ltd. specializes in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc. Providing one-stop service(casting/forging+precision machining+surface treatment), to save time and costs and reduce risk of quality control for you.With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market.During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach.

You are welcome to contact us for technical enquiry and business cooperation.(Email:casting@matechin.com)

-

Read More >

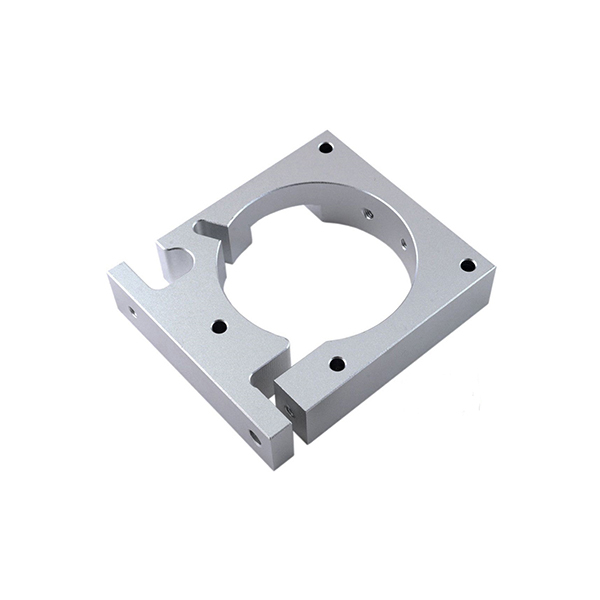

Read More >Machining

-

Read More >

Read More >Forging

-

Read More >

Read More >Casting

15 Year Experience :

over 15 years of rich manufacture experience in the industry.

High Production Capacity :

The capacity is over 1000 tons per month .

A series of furnace covers 250kgs to 500KGS and 1 tons per furnace , to adapt to different size of castings.

One Stop Service :

Matech industry Ltd. can supply ONE-STOP service to you

Details-

2024-05-13

Recently, Matech had the honor of participating in the 2023 GMTN show held in Dü...

-

2021-11-10

Silica sol processSilica sol process belongs to investment casting,precisioncast...

-