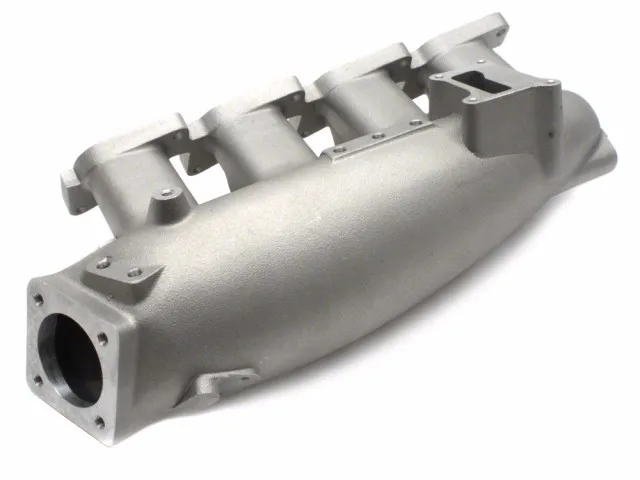

- Customized according to customer's requirement

- Material:A356, AlSi7Mg, ZL101, ADC12, A-S7G

- Car Model:As customer request

- Supply Ability: 150 Ton/Tons per Month of accessories manufacture

Custom Intake Manifold Accessories Seal Ring Machining Manufacturer

uiry and business cooperation.

Our Aluminum Casting Foundry

Our Machining Plant

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years’ export experience for designing and producing vehicle machinery parts.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.

We supply one-to-one custom made service.