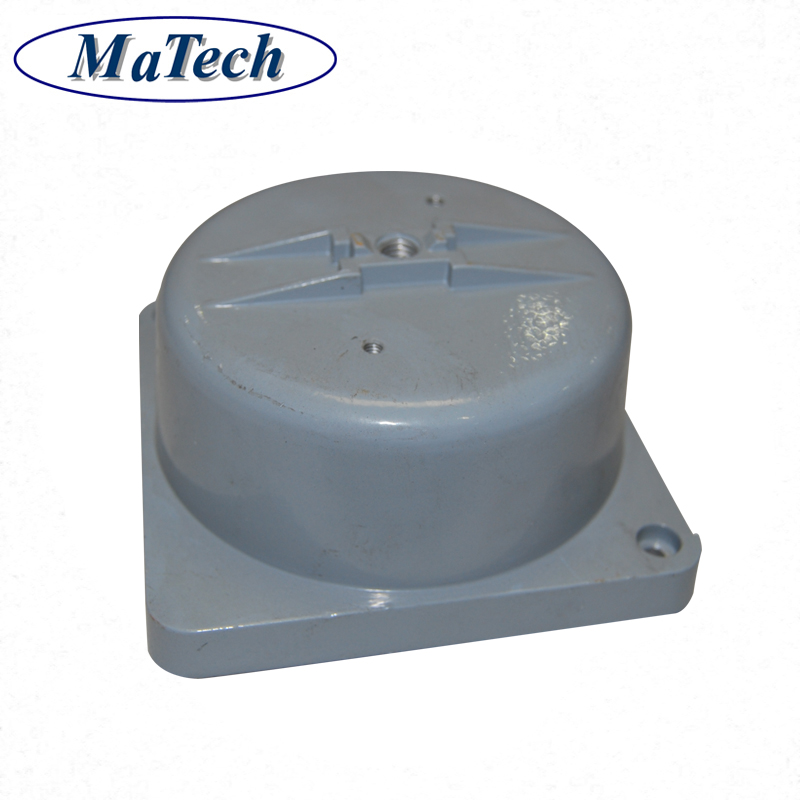

- Material:A380,ADC12 or as customer's requirements

- Process:Casting +Machining(if Need)+surface Treatment

- Surface Finished:Sandblasting, painting, polishing or as customer's requirements

- Drawing Format:pdf,stp,step,stl,etc

- Package:Big Plastic Bag Inside,Multilayer Wooden Box outside

- Delivery time:For sample about 45 days

OEM Cast Aluminum Water Pump Vertical Hot Chamber Die Casting

SINCERITY QUALITY COMPETENCE

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market .

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

Thanks you for your time to view detaield our company information.If you have any questions please feel free to contact us Now!

Raw material

Machining plant

Open The Die

Die casting Machines

Permanent casting

Surface treatment: Sandblasting

Surface treatment:Powder coating process

Machining

Matech attend the GIFA 2019 in Germany

Matech attend the GIFA 2019 in Germany

Customer's comments

Customer's comments

Customer's comments

Customer's comments

Inner Packaging

Outer Packaging

We supply one-stop service, including casting and machining and surface treatment in house