China Foundry Steel Investment Casting Same United Tractor Part

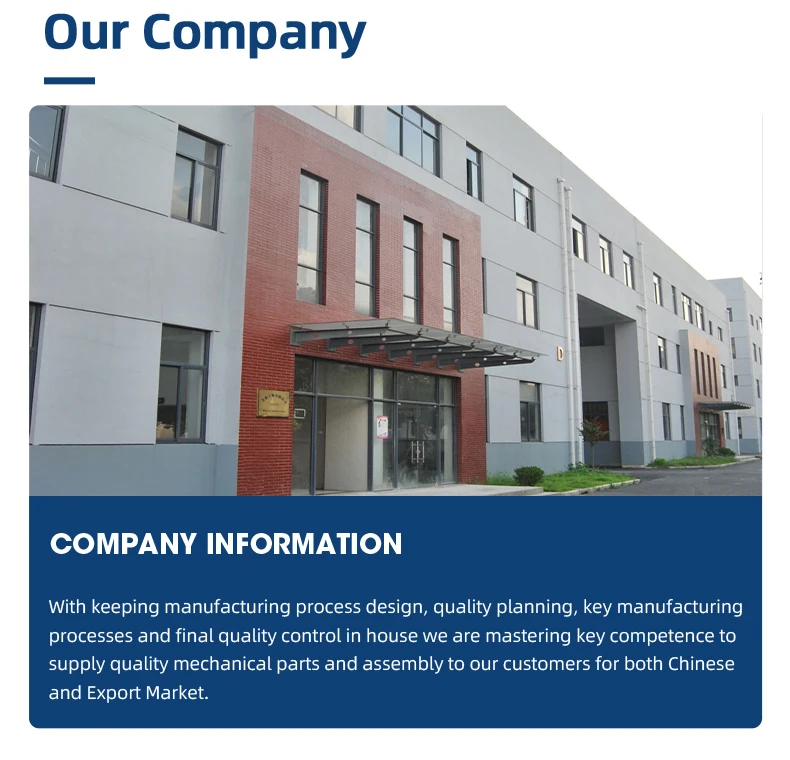

- At MATECH, we want to exceed your expectations by delivering the most economical solution for your product manufacturing needs. We do this by constantly evolving what we do, and finding new ways to improve your current products, that will ultimately drive down costs and increase overall performance.

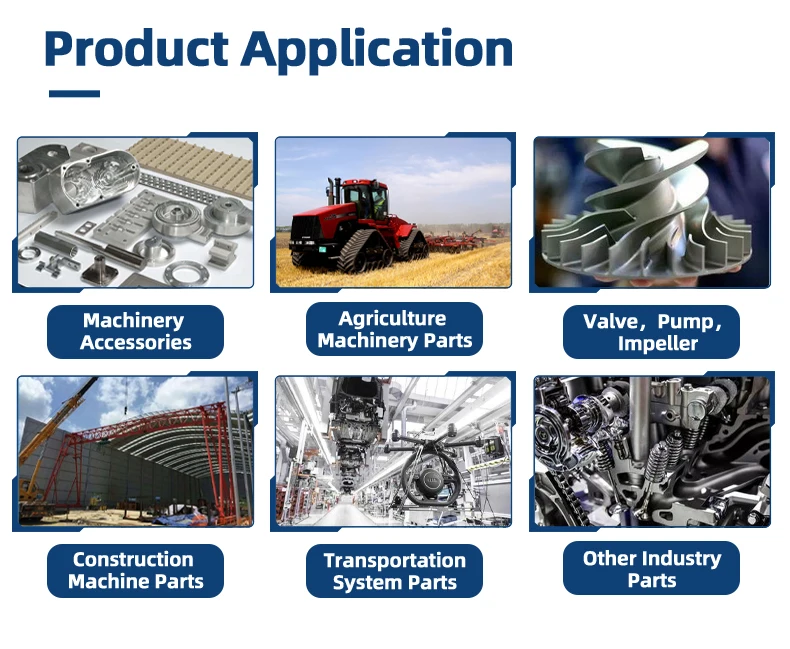

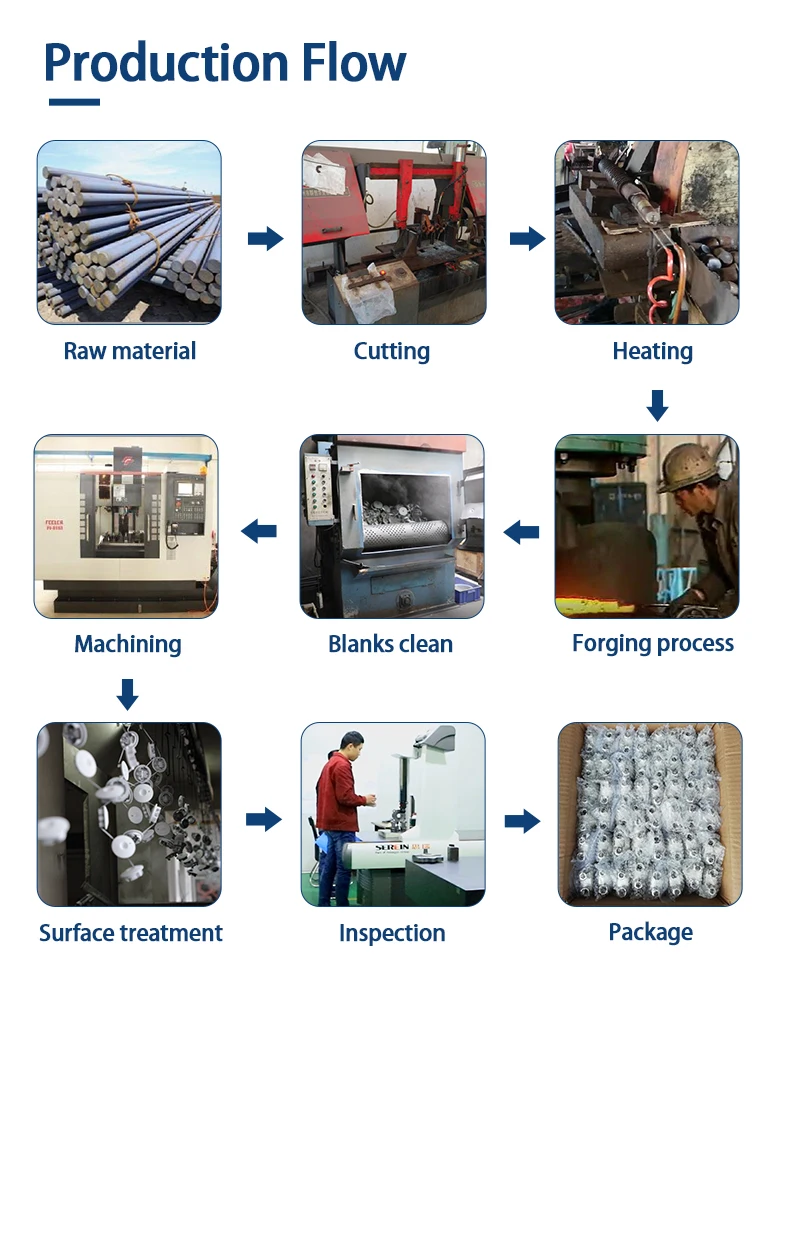

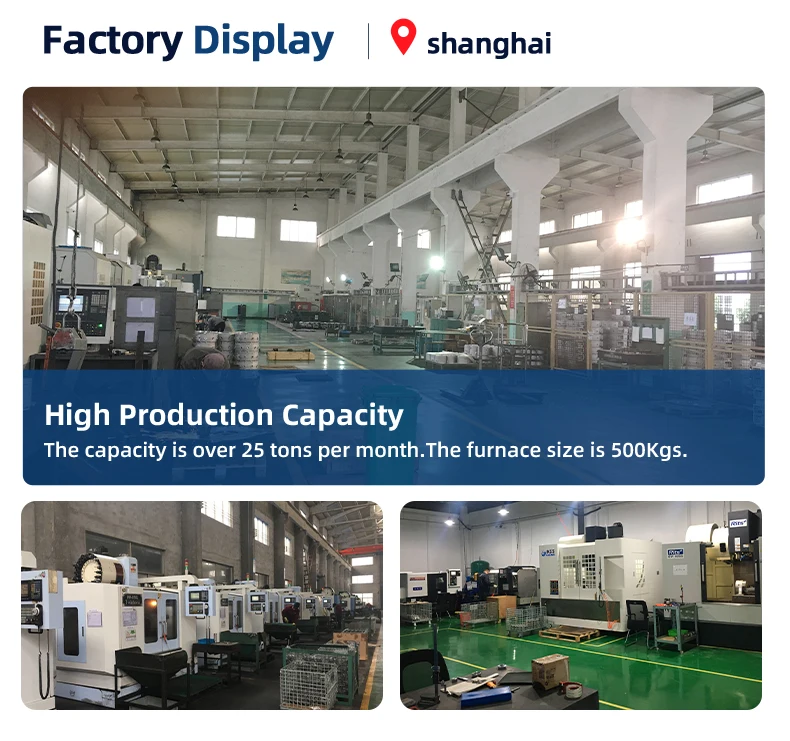

- With our extensive experience in casting, forging, fabrication and machining, we can provide the best production method to manufacture your products. Provide quality finish components based on casting and precision machining in competitive price and on-time delivery for vehicle business and manufacturing industry.

China Foundry Steel Investment Casting Same United Tractor Part

SINCERITY QUALITY COMPETENCE ENTERPRISING

Products Description

FAQ

Welcome your inquiry at any time.