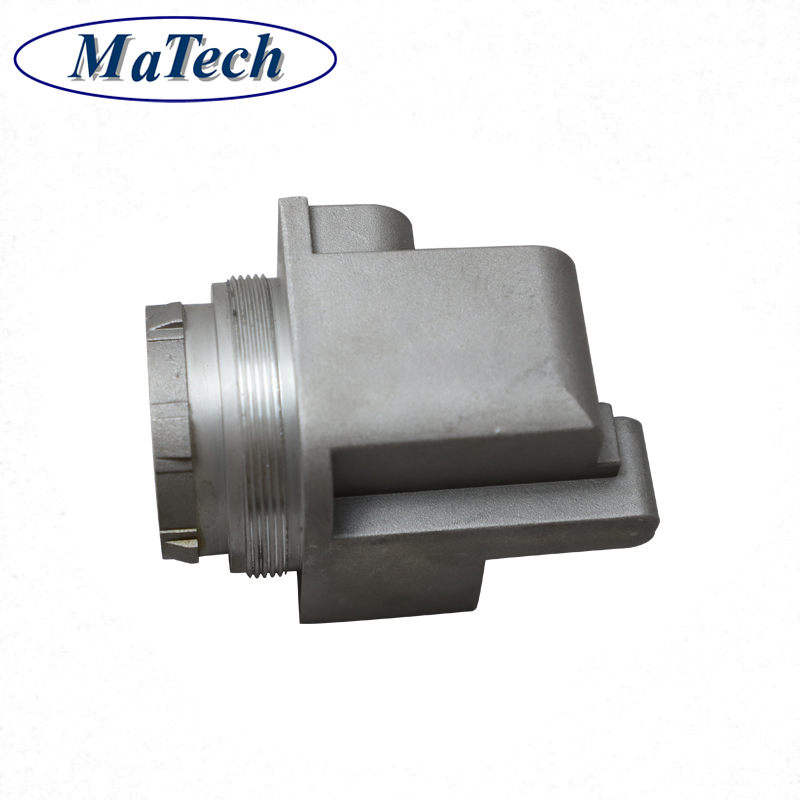

- Brand Name: MATECH

- Material: Zinc ,or as customer's requirements

- Process: Casting +Machining(if Need)+surface Treatment

- Surface Finished: Sandblasting, painting, polishing or as customer's requirements

- Drawing Format: pdf,stp,step,stl,etc

- Certificate: ISO,or as customer's needs

- Package: Big Plastic Bag Inside,Multilayer Wooden Box outside

- Delivery time: about 45 days

- Welcome to contect us!

- Jessica's Email:matech011@matechin.com

MATECH Customized Service Product Zinc Die Casting Alloys

SINCERITY QUALITY COMPETENCE

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

Die casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Depending on the type of die casting, you need to use a cold chamber die casting machine or a hot chamber die casting machine. The cost of casting equipment and molds is high, so the die-casting process is generally only used for mass production of a large number of products. Manufacturing die-cast parts is relatively easy, which generally only requires four main steps, and the individual cost increment is very low. Die casting is particularly suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used one among various casting processes. Compared with other casting technologies, the die-casting surface is flatter and has a higher dimensional consistency.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc.

With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market .

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

Thanks you for your time to view detaield our company information.If you have any questions please feel free to contact us Now!

Raw material

Machining plant

Open The Die

Die casting Machines

Permanent casting

Surface treatment: Sandblasting

Surface treatment:Powder coating process

Machining

Matech attend the GIFA 2019 in Germany

Matech attend the GIFA 2019 in Germany

Customer's comments

Customer's comments

Customer's comments

Customer's comments

Inner Packaging

Outer Packaging

Welcome to contact for more details.