- Material: Aluminum or other metal. As clients require

- Manufacturing Process: casting, machining

- MOQ: 1pc sample for test is available

- Lead Time: About 40 days for casting

- Package of stamping: Multilayer wooden box with big plastic bag inside, as customer request

- Service: Custom Make Part with factory price

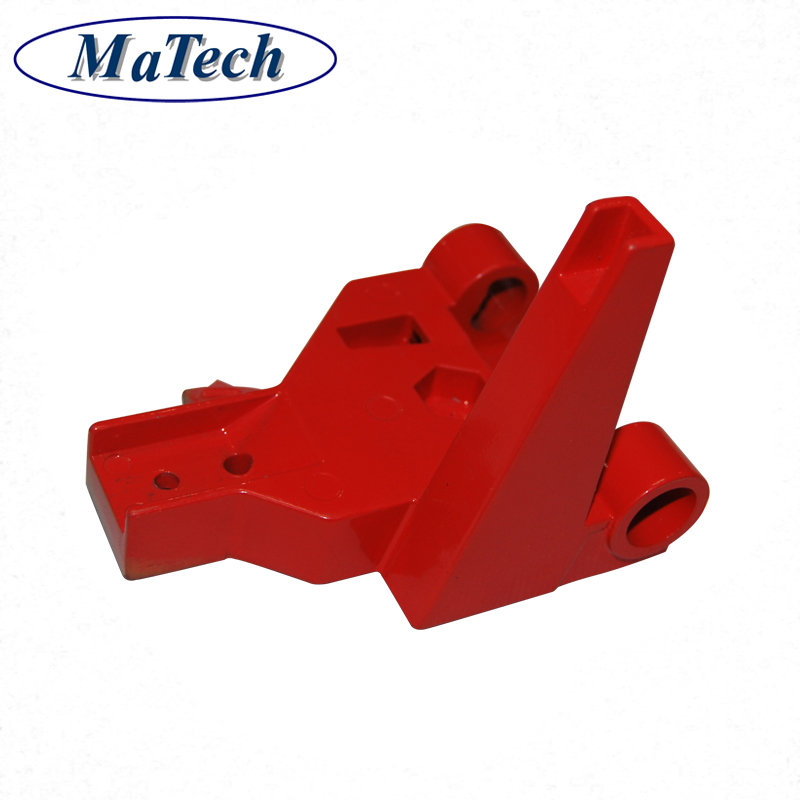

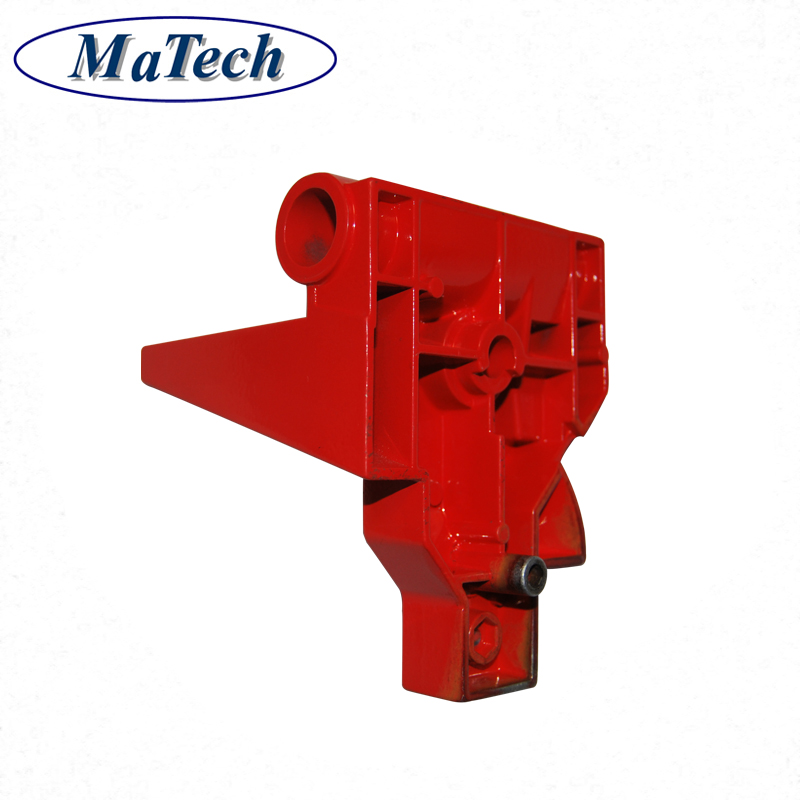

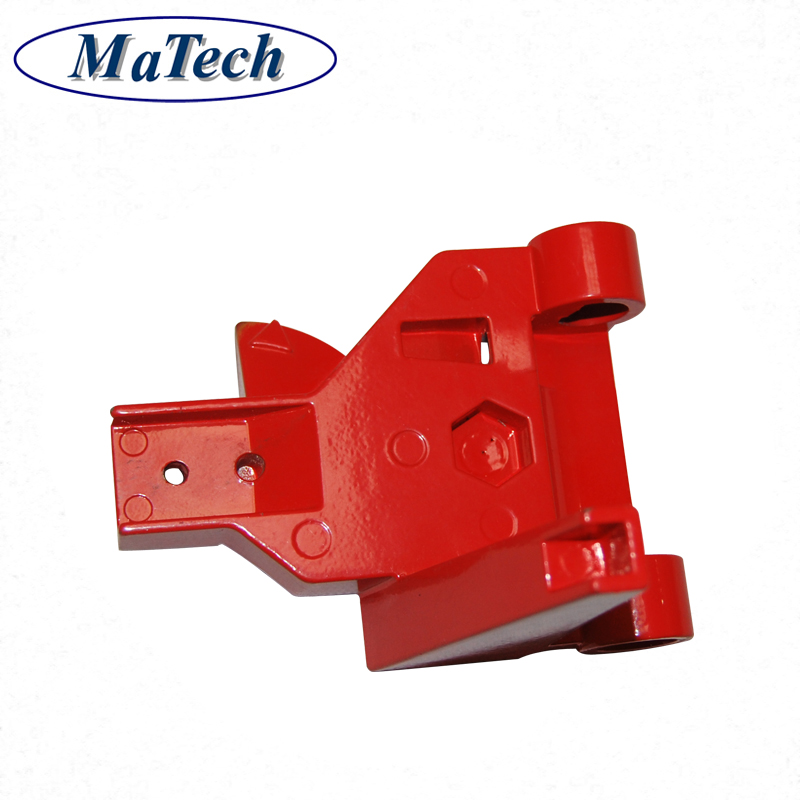

Aluminum Alloy Anodized Die Casting Bracket With Machining

Aluminum Alloy Anodized Die Casting Bracket With Machining

Item Name | Aluminum Alloy Anodized Die Casting Bracket With Machining |

General Products Application/Service Area |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

Main blank Process for Aluminum Casting | Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, High Pressure Casting/Sand Casting, Extrusion Casting etc. |

Blanks Tolerance -Casting Tolerance | CT4-6 for Permanent Molding, Die Casting, CT 9-11 for Sand Casting |

Applicable Material for die casting |

Aluminum Alloy A380 ADC12; Zinc Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2 Or according to customer requirements

|

Casting Blank Size /Dimensions | 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

Casting Blank Weight | Range from 0.01kg-50kg |

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

Applicable Finish Surface Treatment | Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating, Finish Painting, Anodize (White or Black Color) |

MOQ of mass production | For die casting bracket: 100pcs, or as client required For Machining: 50pcs |

Lead Time | 45days from the receipt date of deposit for die casting bracket |

FAQ:

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: Terms of payment for tooling: T/T 60% with the tooling order, the balance to be paid upon the samples' approval.

B: Term of Payment for Samples: T/T 100% with the order, the samples cost will be quoted when clients require.

C. Term of Payment for Batch Shipment: T/T 30% with the order, the balance to be paid before the delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.or as customer's requirements.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce die casting bracket according to the samples?

A: Yes, we can produce die casting bracket by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

We produce metal parts, brackets, housings, shafts etc., and focus on cost reduction and feasible tech proposals for you. Inq